The solvent evaporator for fast and easy evaporation of DMSO, DMF, and water.

BioChromato's Smart Evaporator™ saves time and cost by removing solvents quickly and easily. DMSO, DMF and even water are easily removed without the risk of bumping.

|  |

*1 Total worldwide installations of all Smart Evaporator™ models in universities, public institutions, and private companies. Two hundred installations in the USA. (as of April 2023)

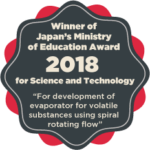

*2 The 42nd Invention Award in 2017 (the Japan Society for the Advancement of Inventions)

Why "Smart Evaporator™"?

DMSO / DMF / water Evaporator

The Smart Evaporator enables efficient evaporation of high boiling point solvents. With the inert gas purging feature (ex. nitrogen), it’s great for drying down solvents such as DMSO, DMF and water.

(inert gas recommended).

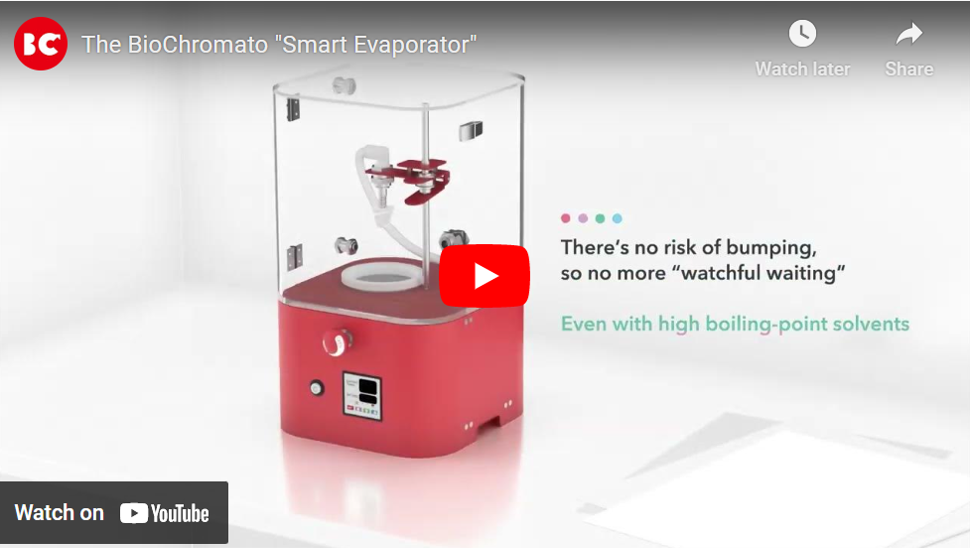

Bump Free Technology

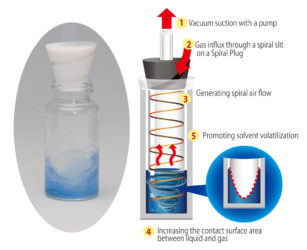

The novel Spiral Plug technology generates a helical flow of air or inert gas over the surface of your solvent, thereby increasing the surface area. Since the vial isn’t under high vacuum, there is no risk of bumping or splashing.

In Vial Evaporation

The Spiral Plugs come in various sizes for compatibility with many different sample tubes, flasks, and vials. Coupled with a quick release, the Spiral Plugs are easily exchangeable between different sizes.

Explore Smart Evaporator's Cutting-edge Technology

Models

Single Channel

Single Channel

for acid samples

4-Channel

8-Channel for microtubes

10-Channel

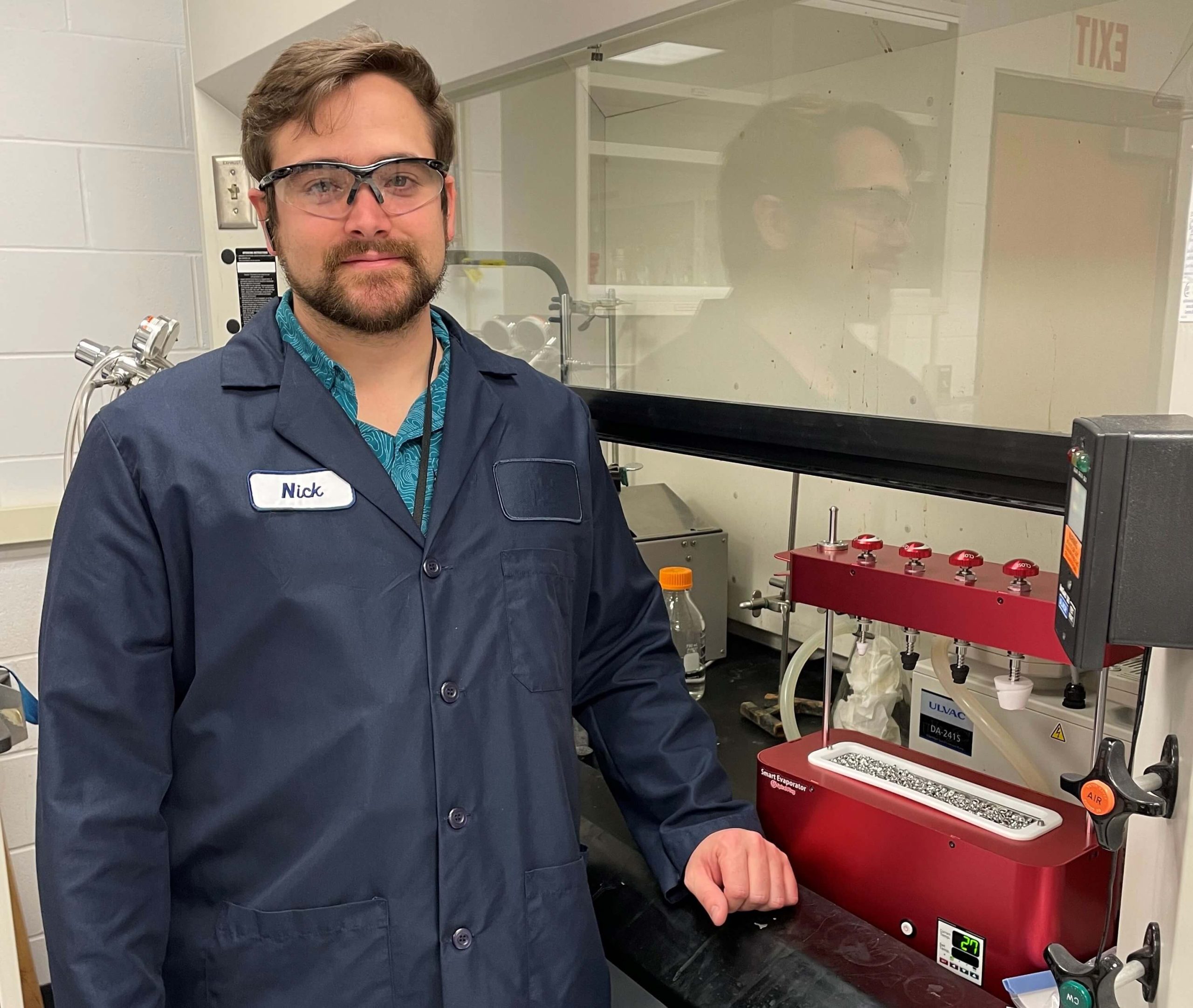

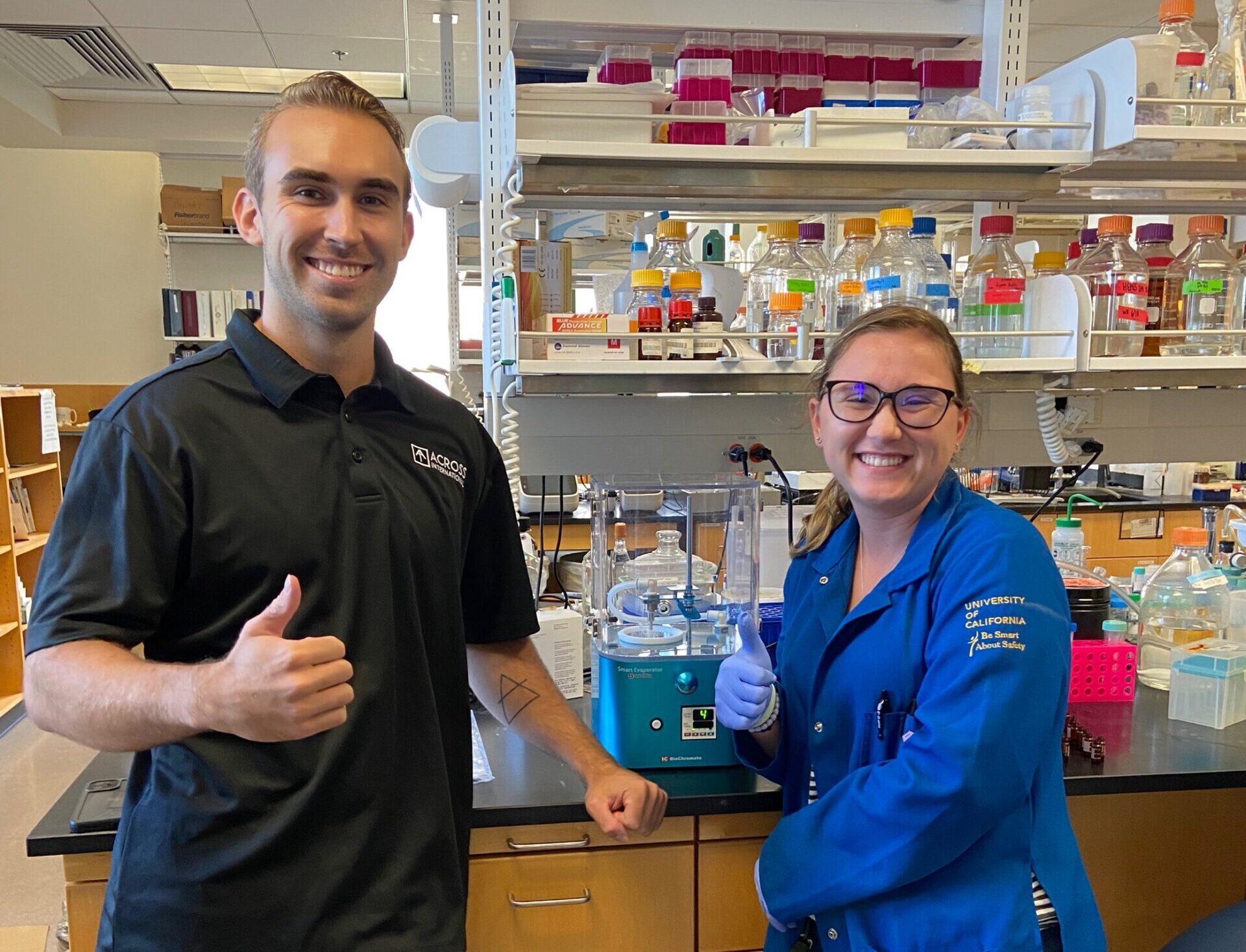

Testimonials from our valuable customers

Thank you for all your valuable testimonials!

You can read how they like using the Smart Evaporator.

Discover the Future of Evaporation

Experience the Difference

Poster/Application

・Smart Evaporator Verification of Enzyme Activity

・Container characteristics during drying and concentration

Publications

Roberta De Bellis, Luca Giorgi, Mariano Stornaiuolo, Carmen Formisano, Andrea Gorassini, Mauro Formica, Eleonora Macedi, Tatjana Stefanovic, Laura Chiarantini

Pharmacological Research - Natural Products, Available online July 3, 2025

For more publications, click here!

Transform Your Laboratory Experience with BioChromato's Smart Evaporator

Discover the Future of Evaporation

Experience the Difference