Comprehensive Strategies for Effective DMSO Removal in Research Laboratories

<Index>

1. Introduction: The Challenge of DMSO Removal in Scientific Research

2. Traditional Methods for DMSO Removal: Challenges and Limitations

2-1. Rotary Evaporation – A Common Yet Suboptimal Approach

2-2. Lyophilization (Freeze Drying) – Effective but Slow

2-3. Alternative Techniques and Their Drawbacks

3. Advanced DMSO Removal Techniques: Faster and More Efficient Solutions

3-1. Vacuum Vortex Concentration(VVC) – A Breakthrough in Solvent Removal

3-2. Why Smart Evaporator™ is the Superior Choice for DMSO Removal

3-3. Real-World Applications of Smart Evaporator™

4. Selecting the Right DMSO Removal Method for Your Research Needs

1. Introduction: The Challenge of DMSO Removal in Scientific Research

Dimethyl sulfoxide (DMSO) is an essential solvent in biological and chemical research due to its ability to dissolve both polar and nonpolar compounds. It is widely used in drug discovery, cryopreservation of cells, and as a reaction medium in organic synthesis. However, its high boiling point and strong solvent properties make its removal difficult. Inefficient DMSO removal can result in:

- Sample degradation and compromised data quality

- Loss of valuable analytes

- Lengthy evaporation times that hinder lab efficiency

- Potential contamination due to solvent residues

- Challenges in downstream processing and analysis

This article explores the most effective DMSO removal techniques and provides insights into optimizing your workflow for improved sample recovery, laboratory productivity, and overall research success.

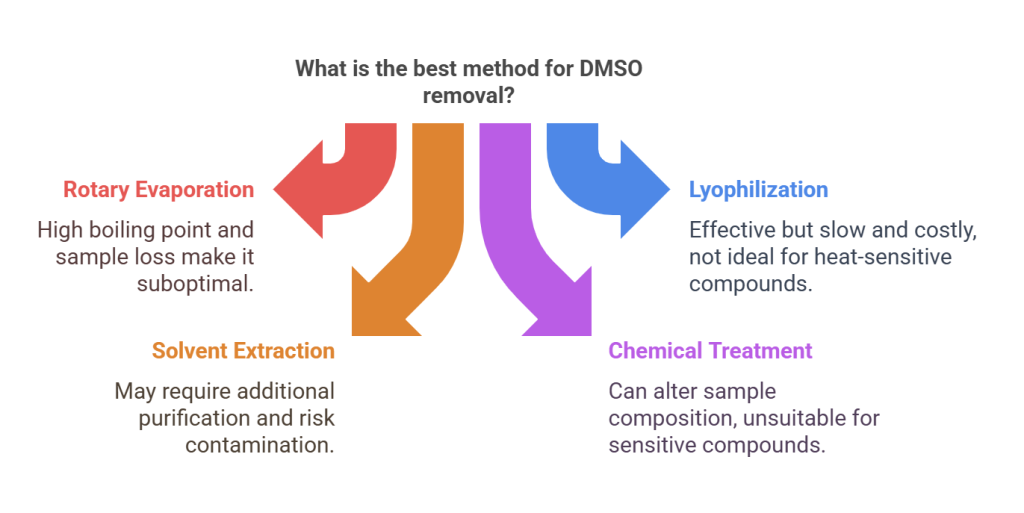

2. Traditional Methods for DMSO Removal: Challenges and Limitations

2-1. Rotary Evaporation – A Common Yet Suboptimal Approach

Rotary evaporators (rotovaps) are a widely used method for solvent removal, but they present significant limitations when handling DMSO:

- High boiling point: DMSO’s boiling point of 189°C requires elevated temperatures, increasing the risk of thermal degradation.

- Bumping and sample loss: Volatile samples frequently experience sudden boiling, leading to potential sample loss.

- Time-intensive process: The evaporation process is slow and requires constant monitoring, making it labor-intensive.

- Inconsistent results: Variability in solvent removal efficiency can impact reproducibility.

2-2. Lyophilization (Freeze Drying) – Effective but Slow

Freeze drying is another common approach for removing DMSO, particularly for biological samples. However, it has several disadvantages:

- Requires freezing and vacuum drying, significantly extending processing times.

- Not ideal for heat-sensitive compounds, as freeze-drying conditions can still impact molecular integrity.

- High operational costs, requiring expensive equipment and ongoing maintenance.

- Limited scalability, making it impractical for high-throughput laboratories.

2-3. Alternative Techniques and Their Drawbacks

Other methods, such as solvent extraction and chemical treatments, have been explored for DMSO removal, but they often introduce new challenges:

- Solvent extraction: May require additional purification steps and can lead to sample contamination.

- Chemical treatment: Can alter sample composition and is not always suitable for sensitive compounds.

3. Advanced DMSO Removal Techniques: Faster and More Efficient Solutions

3-1. Vacuum Vortex Concentration(VVC) – A Breakthrough in Solvent Removal

New-generation Vacuum Vortex Concentration technology, such as Smart Evaporator™, offers a highly efficient alternative to traditional methods. This approach utilizes spiral airflow to:

- Eliminate bumping by maintaining controlled evaporation conditions.

- Significantly reduce processing times compared to conventional evaporation techniques.

- Operate at lower temperatures, preserving sample integrity and preventing thermal degradation.

- Simplify sample handling by eliminating the need for additional solvent dilution.

- Accommodate a wide range of solvents, making it a versatile choice for different applications.

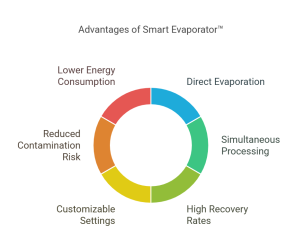

3-2. Why Smart Evaporator™ is the Superior Choice for DMSO Removal

Research institutions worldwide, including Purdue University and the University of Tokyo, are adopting Smart Evaporator™ for its precision, efficiency, and reliability in solvent removal. Studies have demonstrated its ability to minimize sample loss while accelerating evaporation, making it an optimal choice for high-throughput laboratories. Key advantages include:

- Direct evaporation of DMSO without dilution, ensuring accurate concentration.

- Simultaneous processing of multiple samples, optimizing laboratory workflows and improving throughput.

- High recovery rates for valuable compounds, reducing waste and preserving research integrity.

- Customizable settings, allowing researchers to tailor temperature, airflow, and vacuum levels to specific sample needs.

- Reduced contamination risk, as samples remain contained throughout the process.

- Lower energy consumption, making it a cost-effective and sustainable solution.

3-3. Real-World Applications of Smart Evaporator™

The Smart Evaporator™ has been successfully integrated into various research settings, including:

- Drug Discovery – Rapid solvent removal for compound screening.

- Biotechnology – Sample preparation for high-throughput screening.

- Chemical synthesis – Efficient concentration of reaction mixtures.

- Food and beverage research – Analysis of flavor and nutritional components.

Discover the Smart Evaporator™: The Safer, Simpler Solution for Solvent Removal

4. Selecting the Right DMSO Removal Method for Your Research Needs

Choosing the most suitable DMSO removal technique depends on several factors:

- Type of sample – Heat-sensitive versus heat-resistant compounds.

- Throughput requirements – Whether processing a single sample or multiple samples simultaneously.

- Efficiency goals – Balancing speed and sample preservation to maximize research output.

- Scalability – Ensuring the method aligns with long-term laboratory needs.

- Cost considerations – Factoring in equipment investment, maintenance, and operational expenses.

For researchers seeking a fast, precise, and sample-safe evaporation solution, Smart Evaporator™ using Vacuum Vortex Concentration method is the optimal choice.

📌 Explore real-world applications and expert insights on how Smart Evaporator™ transforms DMSO removal!

🔗 Learn more about the technology here

Discover the Smart Evaporator™: The Safer, Simpler Solution for Solvent Removal