Remove DMSO with no bumping,

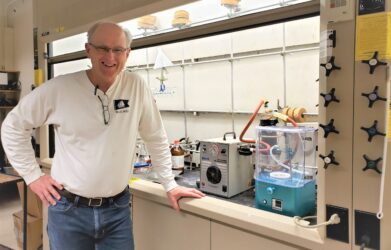

Smart Evaporator C1

Features

- DMSO/DMF/water evaporation with no bumping

- Compatible with various containers

- Minimizes the loss by sample transfer

- Faster evaporation with inert gas

*CE/UL/CSA certified product

Watch the Smart Evaporator™ C1 in operation.

Specification

| Product Name | Smart Evaporator C1 |

| Heater shape & size | Circle shaped, φ69mm |

| Heater temperature range | Room temperature ~ 100℃ |

| Gas Purge | 〇 |

| Inner mouth diameter of compatible containers | φ4~32mm (Examples of compatible containers) |

| Color | 4 colors (Sun, Squall, Sky, Grass) |

| Size (mm) | W220 x D227 x H382 (except protruded parts) |

| Weight | 4.3kg |

| Operating environment | Temperature: 10℃~ to 40℃ Humidity: 20~80% |

*This is a CE/UL/CSA certified product. (CE Certification)

Customers Who Viewed C1 Also Checked Out:

Below are some other popular options:

Smart Evaporator K4

4-Channel Evaporator

Smart Evaporator C10

10-Channel Evaporator

Smart Evaporator ACR1

Acid-Resistant Evaporator

Optional Items

Spiral Plugs

Available in 5 sizes

(for supplement / replacement)

Spiral Plug SP-V series

designed for effective water evaporation

Available in 5 sizes

(for supplement / replacement)

Filter

Available for less contaminated

air-flow (optional)

Vacuum Pump

Is required to operate the Smart Evaporator

(sold separately)

*Are you using the old version (2012-2017) Smart Evaporator C1?

Thank you for your loyalty, and please find the optional items for your C1 from HERE.

Testimonials

*Are you using the old version (2012-2017) Smart Evaporator C1?

Thank you for your loyalty, and please find the optional items for your C1 from HERE.

Video

Watch the video to learn how to use the 4kit.