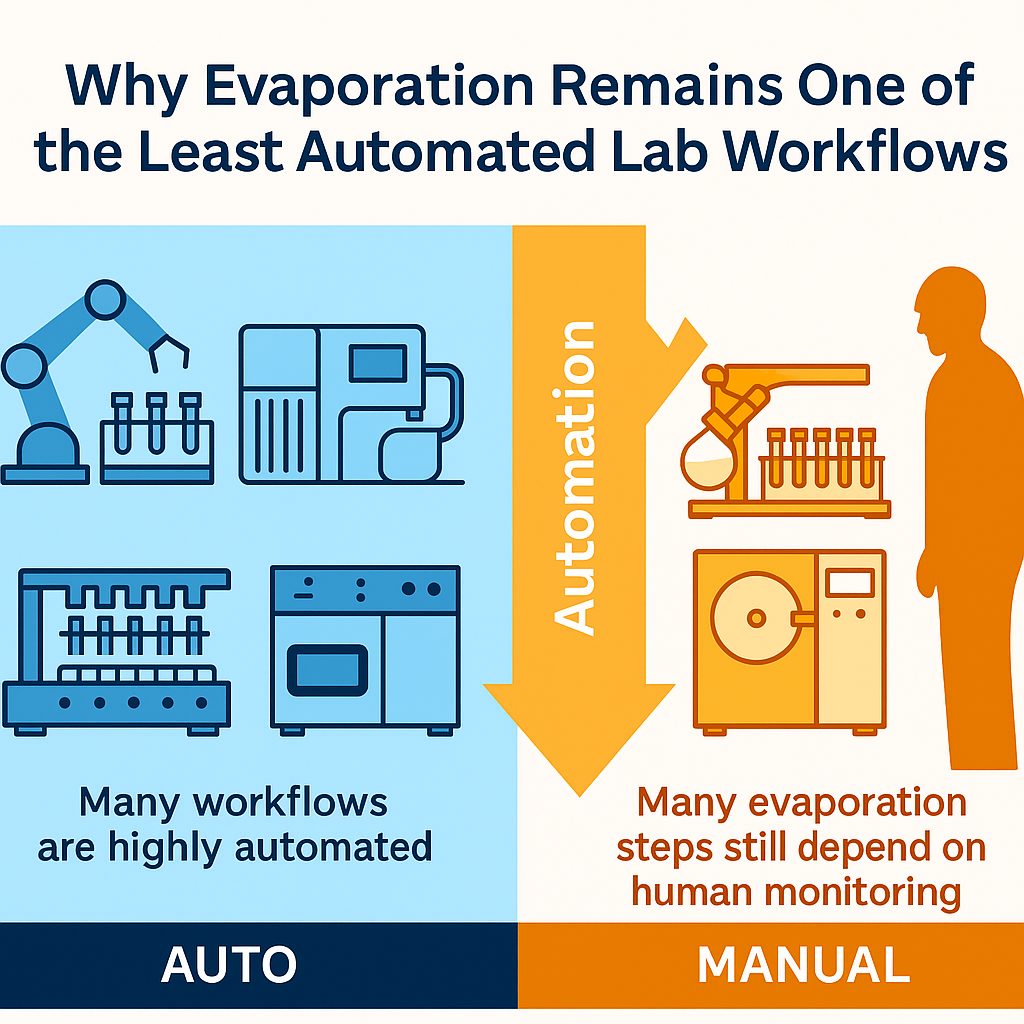

Why Evaporation Remains One of the Least Automated Lab Workflows

Many modern laboratory tasks are now supported by automation, yet solvent evaporation remains one of the slowest and most hands-on steps. Even labs equipped with robots, autosamplers, and high-throughput screening systems still spend significant time monitoring evaporation, adjusting vacuum levels, preventing bumping, or simply waiting. The basic principles and most day-to-day operating practices of evaporation have remained largely unchanged for many years, and many processes still rely on deep vacuum, cold traps, or long freeze-drying cycles that require close human supervision. This article explores why evaporation has remained so difficult to automate in the first place. Understanding the reasons behind this bottleneck helps clarify what laboratories can realistically improve today and why certain steps continue to depend on human judgment.

If you’re exploring ways to simplify evaporation, we’d be glad to help.

Table of Contents

1. Why Evaporation Is Still Hard to Fully Automate in the Lab

1-1. Limitations of Traditional Evaporation Tools

1-2. Why Human Judgment Is Still Required

1-3. Automation vs. Reality: A Comparison

2. The Wide Variety of Solvents and Containers Makes Automation Hard to Standardize

2-1. Why Standardization Is Difficult

2-2. Why Automation Struggles

3. Safety Risks Limit Automation

3-1. Why These Risks Matter

4. Energy and Infrastructure Limit Automation

4-1. Why Energy and Infrastructure Become Barriers

5. New Approaches Help Simplify Evaporation—Even If They Do Not Fully Automate It

5-1. Why Simplification Matters More Than Full Automation

1. Why Evaporation Is Still Hard to Fully Automate in the Lab

Despite advances in laboratory automation, evaporation remains one of the least automated steps in many labs. The reason is simple: most classic evaporation tools were designed for hands-on human control, not for unattended, lights-out operation. Traditional systems such as rotary evaporators, nitrogen blowdown systems, and freeze dryers all require human judgment at key points, making full automation difficult.

1-1. Limitations of Traditional Evaporation Tools

Each common evaporation method has its own constraints when it comes to automation.

Rotary evaporators

Require careful vacuum adjustment to avoid bumping

Need regular chiller operation and maintenance

Often demand close visual monitoring during evaporation

Nitrogen blowdown systems

Require frequent checks to prevent foaming or overdrying

Operators often monitor remaining solvent volume by eye

Drying behavior can vary widely between samples

Freeze dryers

Use long, multi-step programs that must be carefully designed

Recipe creation and validation rely on expert judgment

Even when cycles run automatically, outcome assessment is often manual

Because these systems were not originally optimized for full, lights-out automation, it is harder to remove human decision-making completely.

1-2. Why Human Judgment Is Still Required

In many modern labs, upstream and downstream processes are already automated.

For example:

Automated synthesis

Automated purification

Automated LC/MS loading

Yet researchers still walk over to the rotavap or nitrogen evaporator to observe evaporation, especially:

During method development

When handling new solvent mixtures

When working with sensitive or high-value samples

The surrounding workflow has evolved—but evaporation often remains a judgment-based step.

1-3. Automation vs. Reality: A Comparison

| Evaporation Method | Automation Level | Human Judgment Still Needed |

|---|---|---|

| Rotary Evaporator | Partial | Vacuum tuning, bumping prevention |

| Nitrogen Blowdown | Low–Moderate | Foaming, volume estimation |

| Freeze Dryer | Moderate | Recipe design, cycle validation |

Traditional evaporators were built for hands-on human control, so even though modern add-ons and new platforms can automate many tasks, achieving fully unattended evaporation across all use cases remains challenging.

Curious how low- and high-boiling solvents change evaporation behavior?

Explore this article next.

👉[Low-Boiling vs. High-Boiling Solvents: Choosing the Best Evaporator]

2. The Wide Variety of Solvents and Containers Makes Automation Hard to Standardize

Evaporation conditions differ widely depending on solvent type, sample volume, and container shape. These variables make it difficult to create a single automated solution.

2-1. Why Standardization Is Difficult

< 1. Solvents Behave Very Differently >

Different solvents evaporate at dramatically different rates and behaviors:

- Water evaporates slowly

- Methanol evaporates quickly

- DMSO and DMF evaporate very slowly

- Some solvent mixtures foam, bump, or behave unpredictably

These differences directly affect evaporation speed, temperature tolerance, and airflow requirements.

< 2. Containers Add Another Layer of Complexity >

Evaporation performance also depends heavily on container type:

- Microtubes

- Vials

- NMR tubes

- Centrifuge tubes

Each container shape responds differently to heat, airflow, and vacuum, further complicating automation.

2-2. Why Automation Struggles

Automation works best when one predictable operating pattern can cover many use cases.

However, evaporation conditions can change dramatically from one solvent–container combination to another.

Human operators can instantly adjust based on visual cues and experience

Automated systems typically rely on predefined, method-specific recipes

A true “one-button” solution becomes impractical when conditions vary so widely

For example, a typical laboratory may evaporate DMF from vials in the morning and water from microtubes in the afternoon.

Each scenario requires a different balance of temperature, airflow, and monitoring. Traditional evaporation systems do not automatically adjust when conditions change, meaning the operator must intervene or select a different predefined method. As a result, workflow is interrupted, and the risk of inconsistency increases.

Because solvent and container behavior vary so much, standard manual setups of traditional evaporators struggle to provide a universal automated response.

3. Safety Risks Limit Automation

Evaporation involves inherent safety risks—such as bumping, foaming, and sample loss—that make fully unattended operation difficult and risky.

3-1. Why These Risks Matter

< 1. Vacuum Can Trigger Sudden, Uncontrolled Boiling>

Under reduced pressure, solvents may boil abruptly, causing samples to:

Bump or foam unexpectedly

Be ejected into condensers

Contaminate collection flasks or adjacent samples

When this happens, both sample integrity and data quality can be compromised in an instant.

< 2. High-Risk Samples Demand Human Oversight >

Because evaporation issues can directly impact downstream experiments, many labs hesitate to automate this step—especially when working with:

High-value compounds

Limited-volume samples

New or unfamiliar solvents

Automation requires predictable, stable behavior. However, vacuum-based evaporation is often inherently unstable without careful, real-time control.

For example, pharmaceutical discovery teams often work with limited-volume, high-value compounds. Even losing a few microliters can impact project timelines. Researchers, therefore, stay close to the evaporator rather than rely on automated control.

Unpredictable boiling behavior limits the suitability of evaporation for hands-off automation.

Concerned about bumping, sample loss, or supervision time?

Read how labs are addressing these challenges in real workflows.

👉 [Rotavap Challenges and Solutions in Chemistry, Food & Pharma]

4. Energy and Infrastructure Limit Automation

Automated evaporation systems often require vacuum pumps, chillers, water baths, and cold traps, making them energy-intensive and challenging to automate efficiently.

4-1. Why Energy and Infrastructure Become Barriers

< 1. Continuous Energy Demand >

Maintaining stable evaporation conditions requires constant input of energy to support:

Vacuum stability

Cooling performance

Controlled evaporation rates

These requirements increase power consumption and system complexity compared with other automated lab instruments.

< 2. Infrastructure Needs Vary Widely >

Some high-capacity automated evaporation systems may require:

Larger vacuum pumps

Chilled water supply

Additional cooling or maintenance infrastructure

While newer, low-energy or compact designs can reduce many of these demands, the requirements still vary significantly across platforms. This variability makes standardization and easy deployment challenging.

< 3. Facility Upgrades and Workflow Disruption >

Many laboratories hesitate to adopt automated evaporation not only due to energy use, but also because:

Facility upgrades can be costly

Installation may disrupt existing workflows

Centralized systems must simultaneously manage:

Energy demand

Sample variability

Bumping and safety risks

When these factors are combined, the perceived complexity often outweighs the expected benefit.

Because of high energy consumption and infrastructure complexity, automated evaporation systems have not achieved the same level of widespread adoption as other automated laboratory technologies.

5. New Approaches Help Simplify Evaporation—Even If They Do Not Fully Automate It

While complete automation of evaporation remains challenging, the Smart Evaporator™ demonstrates how newer approaches can reduce manual workload and deliver more stable, predictable operation without full automation.

5-1. Why Simplification Matters More Than Full Automation

Rather than attempting complete automation, the Smart Evaporator™ focuses on simplifying evaporation workflows and improving usability.

Key aspects of this approach include:

Avoiding deep vacuum conditions, which helps reduce bumping and instability

Allowing evaporation directly in common laboratory containers, reducing setup and cleanup time

Eliminating the need for complex, method-specific programming

This approach is not intended as an automation technology, but as a workflow-simplification solution that supports more consistent day-to-day operation.

Tools such as the Smart Evaporator™ demonstrate how simplification can offer practical advantages over full automation.

By prioritizing stability, predictable behavior, and ease of use—rather than unattended operation—these systems reduce supervision demands and improve consistency in routine evaporation tasks.

Click here to learn more about the Smart Evaporator™

Learn more about a workflow-focused approach to evaporation

—designed to simplify, not automate.

👉 [How the Smart Evaporator™ Works]

6. Summary

Many laboratory workflows—especially in synthesis, purification, and analytical measurement—have advanced rapidly through automation. Yet solvent evaporation remains one of the least automated steps in modern labs. Traditional evaporators depend heavily on human judgment to control vacuum levels, solvent behavior, and sample safety, and evaporation conditions vary widely across solvents, container formats, and volumes. Safety concerns such as bumping, foaming, and sample loss further reinforce the need for monitoring, especially with limited or unfamiliar samples.

Energy and infrastructure requirements also shape automation decisions. While some high-capacity systems may require additional pumps, chilled water, or maintenance to support automated operation, newer compact and low-energy designs can reduce this burden. Even so, facility upgrades and workflow disruptions remain significant considerations. As a result, evaporation continues to rely on human oversight and is likely to do so until sensing, feedback, and control technologies advance further.

If you’re exploring ways to simplify evaporation, we’d be glad to help.

Learn More

- Biotage. Automating Sample Prep Boosts Analytical Lab Efficiency

- The University of New South Wales. Rotary Evaporator Safe Work Procedure

- University of Illinois at Urbana-Champaign. ROTARY EVAPORATOR-Standard Operating Procedure

- Lab Unique. Rotary Evaporator Solvent Chart – Lab Unique

- LinkedIn. The Hidden Cost of Sample Preparation: How Efficient Evaporation Transforms Laboratory Productivity

- BioChromato.How does the Smart Evaporator™ work?.

📚 Related Articles

- Rotary Evaporator vs. Energy-Efficient Alternatives: How to Cut Evaporation Time and Power Usage👉 Read the full article here