Low-Boiling vs. High-Boiling Solvents: Choosing the Best Evaporator

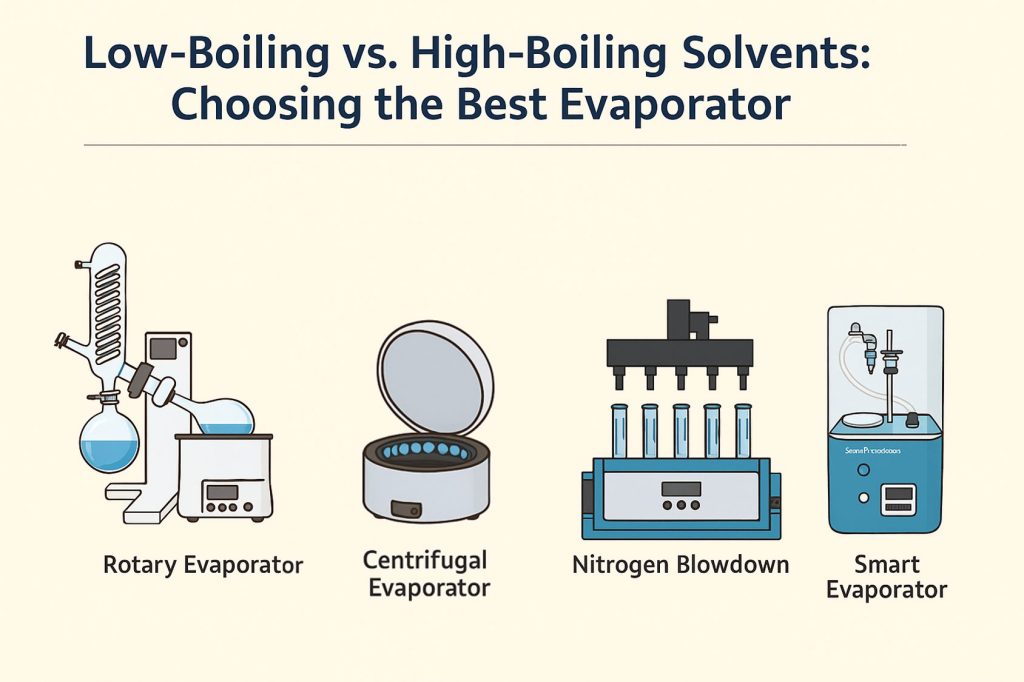

When removing solvents in the lab, selecting the right evaporation method depends not only on the solvent’s boiling point but also on sample volume, desired throughput, and handling convenience. While rotary evaporators are the most widely used, other techniques—including centrifugal evaporators, nitrogen blowdown, and the Smart Evaporator—offer distinct advantages in specific scenarios. This article compares these approaches and suggests practical solutions for both low- and high-boiling solvents.

When removing solvents in the lab, selecting the right evaporation method depends not only on the solvent’s boiling point but also on sample volume, desired throughput, and handling convenience. While rotary evaporators are the most widely used, other techniques—including centrifugal evaporators, nitrogen blowdown, and the Smart Evaporator—offer distinct advantages in specific scenarios. This article compares these approaches and suggests practical solutions for both low- and high-boiling solvents.

Index

- 1. Evaporating Low-Boiling Solvents

- 2. Evaporating High-Boiling Solvents

- 3. Comparing Evaporation Methods (with solvent examples)

- 4. Why Smart Evaporator Matters for Small Volumes

- 5. Practical Tips for Faster, Safer Evaporation

- 6. Conclusion & Recommended Workflow

- 7. Frequently Asked Questions

1. Evaporating Low-Boiling Solvents

Typical examples: diethyl ether (~35 °C), acetone (~56 °C), methanol (~65 °C), hexane (~69 °C), ethyl acetate (~77 °C), ethanol (~78 °C), acetonitrile (~82 °C).

Rotary Evaporator

- Best fit: bulk removal and routine concentration of ethanol, acetone, methanol, acetonitrile.

- Why it works: rotating thin film under vacuum increases surface area for fast evaporation.

- Watch-outs: bumping on very volatile solvents (e.g., diethyl ether); setup overhead for very small volumes.

Nitrogen Blowdown

- Best fit: parallel small/medium tubes for volatile solvents such as acetone, hexane, ethyl acetate.

- Watch-outs: requires supervision; potential aerosol/cross-contamination; not ideal for high-boiling solvents.

Centrifugal Evaporator

- Best fit: plates/racks under vacuum to reduce bumping across many wells for acetonitrile or methanol mixtures.

- Watch-outs: slower for high-boilers; rotor format dictates capacity.

Smart Evaporator

- Best fit: small volumes (0.5–50 mL) of acetone, acetonitrile, methanol, ethanol directly in vials or flasks—minimal setup, bump-free, no vacuum.

- Watch-outs: not intended for bulk low-boiling removal from large flasks.

2. Evaporating High-Boiling Solvents

Typical examples: DMF (~153 °C), toluene (~111 °C), DMSO (~189 °C), NMP (~202 °C) and even water (~100 °C). While water may sound straightforward, its higher boiling point than many organic solvents—and high heat of vaporization—makes evaporation slower and more energy-intensive. Efficient removal typically requires reduced pressure and careful bumping control.

.

Rotary Evaporator

- Possible but demanding: requires deep vacuum and higher bath temperatures for DMF, DMSO, and water when large volumes are present.

- Limits: bumping risk and long process times.

Centrifugal Evaporator

- Pros: vacuum + centrifugal force mitigate bumping in plates/tubes; useful also for aqueous eluents (e.g., acetonitrile/water, methanol/water).

- Limits: still slow for DMSO/NMP; limited by rotor capacity.

Nitrogen Blowdown

- Not recommended: inefficient for DMSO, DMF, NMP; risk of crusting at liquid surface and for large volumes of water; risk of crusting at the liquid–gas interface.

Smart Evaporator

- Best fit: small volumes of DMF, DMSO, NMP, toluene and water-based samples —operated at atmospheric pressure with a stable vortex to prevent bumping and foaming.

3. Comparing Evaporation Methods

| Method | Best For | Limitations |

|---|---|---|

| Rotary Evaporator | Bulk removal of low-boilers: ethanol, acetone, methanol, acetonitrile; also mid-boilers like ethyl acetate, toluene. | High-boilers (DMSO, DMF, NMP) need deep vacuum; bumping risk for volatile solvents (diethyl ether). |

| Centrifugal Evaporator | Plate/tube formats: acetonitrile/water, methanol/water mixtures. | Slower for DMSO, DMF; vessel format restricted. |

| Nitrogen Blowdown | Volatile solvents in small tubes: acetone, hexane, ethyl acetate. | Inefficient for DMSO, DMF; needs supervision. |

| Smart Evaporator | Small-volume evaporation of both low- (acetone, methanol) and high-boilers (DMSO, DMF, NMP, water). | Not for bulk scale; throughput limited. |

4. Why Smart Evaporator Matters for Small Volumes

The Smart Evaporator is often associated with high-boiling solvents like DMSO and DMF—and for good reason. Its ability to evaporate these difficult solvents without vacuum makes it a standout solution. But this is only part of the story.

Where the Smart Evaporator truly shines is in small-volume evaporation, regardless of the solvent’s boiling point. Many labs struggle to efficiently remove low-boiling solvents such as acetone, ethanol, or acetonitrile when working with just a few milliliters. Rotary evaporators are often overkill for such tasks. Nitrogen blowdown requires close attention and risks splashing.

In contrast, the Smart Evaporator enables fast and safe evaporation directly in existing containers—no bumping, no vacuum, no glassware switching. For example, researchers needing to evaporate DMSO safely without bumping can rely on its vortex airflow, which stabilizes even viscous or high-boiling solvents.

Whether drying methanol from small tubes or gently removing NMP, the Smart Evaporator makes small-volume solvent removal fast, reproducible, and hands-free.

Ready for Safer, Faster, and More Reliable Evaporation?

5. Practical Tips for Faster, Safer Evaporation

Even with the right equipment, optimizing your evaporation workflow requires attention to detail. Below are some field-tested tips to improve speed, safety, and reproducibility—particularly when working with challenging solvents like DMSO, DMF, or NMP.

- Match method to solvent and volume: Rotary for bulk low-boilers; Smart for small-volume or high-boilers; Centrifugal for plates; Nitrogen for quick volatile removal.

- Choose the right container: Wide-mouth flasks or vials shorten evaporation time. For Smart, fill 30–50% of container volume to maximize vortex efficiency.

- Prevent bumping: On rotary, use gradual vacuum control. On Smart, bumping is naturally suppressed—even for acetonitrile or DMSO.

- Minimize transfers: Evaporating directly in vials/tubes reduces contamination and loss. Smart supports direct evaporation without special glassware.

- Combine technologies: Pre-concentrate bulk on Rotary, finish drying on Smart to save time and ensure sample integrity.

6. Conclusion & Recommended Workflow

There is no single best evaporator for every scenario. Each method—rotary, centrifugal, nitrogen blowdown, and Smart—has strengths that make it ideal for specific workflows, solvents, and sample volumes.

For bulk low-boiling solvents like ethanol or acetone, the rotary evaporator remains the gold standard. For high-throughput plate formats, centrifugal evaporators are useful. Nitrogen blowdown works for volatile solvents but needs supervision.

However, for small-volume evaporation—whether with acetone, methanol or DMSO, DMF, NMP—the Smart Evaporator fills a unique role. Its bump-free, vacuum-free operation saves time, improves safety, and reduces handling steps.

Many labs now combine Rotary and Smart: bulk pre-concentration on Rotary, then finishing or delicate solvent removal on Smart. This hybrid approach ensures efficiency, safety, and reproducibility across a wide range of solvents.

Ready for Safer, Faster, and More Reliable Evaporation?

7. Frequently Asked Questions

Q1.How can I evaporate DMSO safely without bumping?

Evaporating DMSO with a rotary requires deep vacuum and heat, often causing bumping. Smart Evaporator enables bump-free evaporation at atmospheric pressure, ideal for small volumes.

Q2.Can I use a Smart Evaporator for low-boiling solvents?

Yes. It performs well with small volumes of acetone, methanol, ethanol, and acetonitrile—without vacuum or bumping.

Q3.What’s the best way to evaporate DMF?

Use Rotary for bulk pre-concentration, then Smart Evaporator for final drying. For small volumes, Smart alone is most effective.

Q4.Can I dry my sample directly in a vial?

Yes. Smart Evaporator supports evaporation directly in vials, tubes, or flasks—minimizing transfers and sample loss.

Q5.Is nitrogen blowdown suitable for high-boiling solvents?

No. Nitrogen blowdown is inefficient for high-boilers like DMSO or DMF. Rotary or Smart Evaporators are better suited.

Q6. How should I handle water during evaporation?

Water (bp 100 °C) often requires reduced pressure on a rotary to speed removal, but can still foam. For small aqueous volumes or sensitive samples, the Smart Evaporator provides stable, bump-free evaporation at atmospheric pressure.