Rotary Evaporator (Rotovap) Issues and the Smart Solution

Evaporation is an integral part of chemistry research and the de facto instrument is the Rotary Evaporator, also referred to as Rotovap. As much as they are commonly used for concentrating solvents, they also have a reputation for issues that include

1. bumping and annihilating substances,

2. slow evaporation, especially for DMSO / DMF and other high-boiling point substances and

3. difficulty working with small volumes,

all of which can present larger problems for your research.

Though Rotary Evaporators do have their use in common applications, as a technology developed over 50 years ago, due to certain design limitations there are certain fundamental issues that cannot be avoided, even when taking the most careful precautions. As a definitive solution to these problems, the Vacuum Vortex Evaporator, also known as the Smart Evaporator was developed to address these common Rotary Evaporation issues. Let’s look at these issues and how vacuum vortex evaporation is designed to address them.

Bumping vs. No Bumping

Bumping is a common problem while using rotary evaporators, as samples being heated under vacuum in closed conditions causes the solvent to suddenly boil and “bump,” in other words erupt, usually quickly without warning. As the rotovap evaporates the solvent under vacuum, the solvent can be sucked up in its entirety, leading to the loss of the sample, not to mention losing time and money.

With the Vacuum Vortex Evaporation technology in the Smart Evaporator, the solvent is rapidly stirred in a airflow-based liquid vortex at steady atmospheric pressure, preventing bumping and sample loss. The secret to this bump-proof technology is the patented spiral plug® technology, which allows for air to continuously flow through the sample vial and rapidly evaporate without the risk of bumping. The key to no bumping is in the fundamental design that doesn’t allow bumping conditions to occur in the first place, as opposed to the burden of having to take precautions.

Slow Evaporation vs. Smart Evaporation

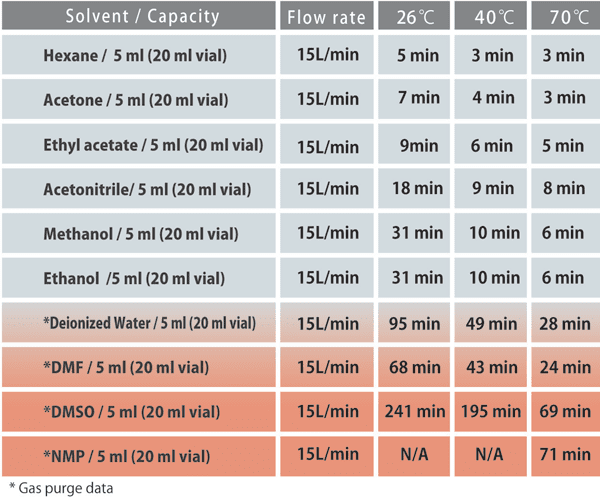

Due to their inherent technological limitations, evaporating solvents with Rotary Evaporators can be painfully slow, especially for high boiling point solvents, such as DMF (Dimethylformamide) and DMSO (Dimethyl Sulfoxide). Researchers know that this orthodox evaporation method using a rotovap can take a very long time and is a large bottleneck in the overall synthesis and recovery process.

Vacuum Vortex Evaporation takes a novel approach in evaporation by using rapid spiral air flow combined with heat to volatilize and quickly evaporate solvents, even the most difficult high-boiling point solvents such as DMSO and DMF. With their high solubility, these very useful solvents can be easily used with the Smart Evaporator in synthesis and sample recovery thereby speeding up your research.

Small Sample Sizes (Painstaking vs. Painless)

Working with rotary evaporators can be difficult, especially with small samples. Transferring the solvent to the rotovap, followed by painstakingly scraping the sample from the round-bottom flask, not only leads to wasted effort, lost time and loss of sample, but also presents risk of cross-contamination.

The Smart Evaporator works by evaporating samples directly in the vial, a process which not only allows for evaporation of small quantities, but also makes for a quick and seamless process. The sample stays in the vial the whole time, so no need to transfer, monitor, scrape, repeat, etc. Simply load the sample in the vial and it will be retained in its entirety, resulting in high recovery rates and low contamination risk, without the need to keep a close eye on the entire process.

Solution to Evaporation Issues

As outlined above, common issues with rotary evaporators such as bumping, slow evaporation times and difficulty with small samples can be eliminated with the Smart Evaporator’s Vacuum Vortex Evaporation technology.

The solution-by-design Vacuum Vortex Evaporation technology is the solution for any operation wishing to bypass common rotovap issues, save time and money and accelerate their research to the next level.

For more information on Smart Evaporator and Vacuum Vortex Evaporation technology, please visit the Smart Evaporator product page, or contact us with your questions.

How much time and how many samples

have been lost already?

Learn how to stop losing time

and valuable sample resources here.