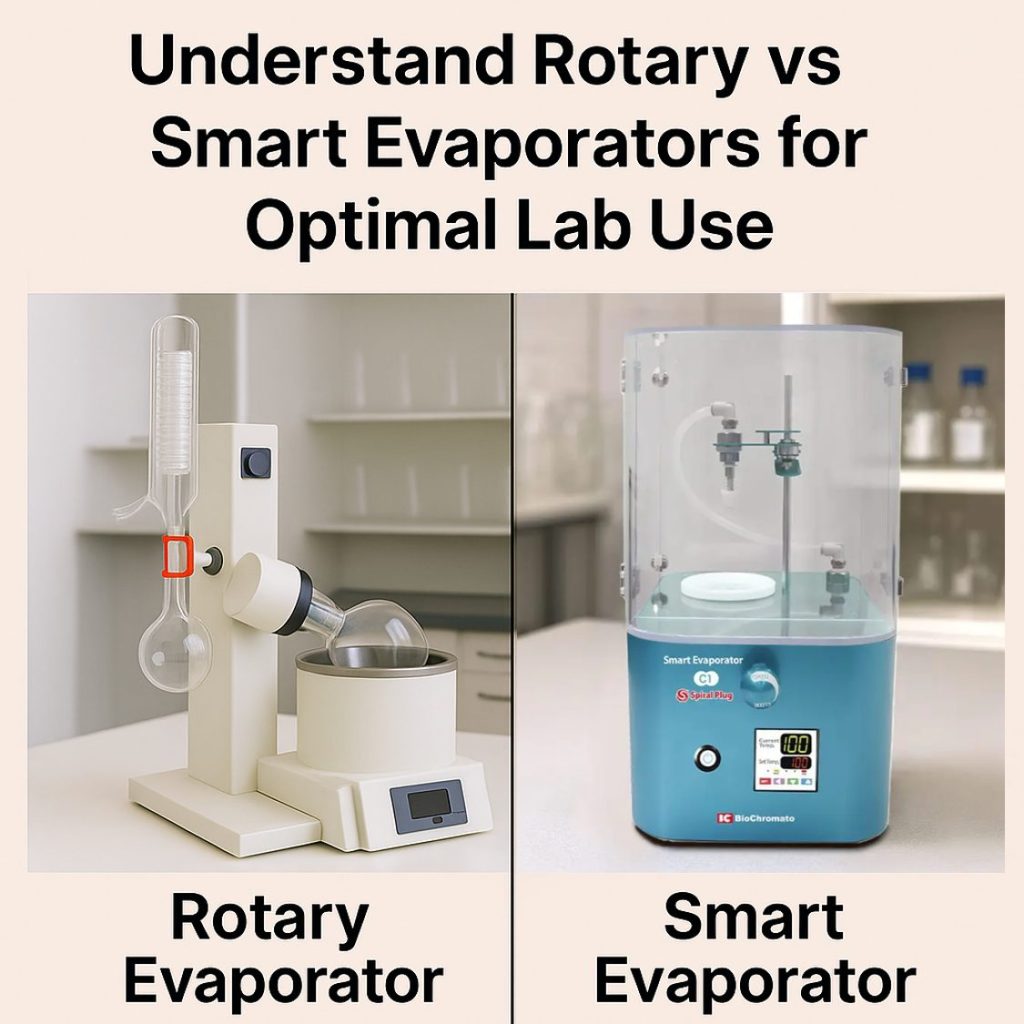

Rotary Evaporator vs Smart Evaporator: Principles and Key Differences

In laboratory sample concentration, the rotary evaporator remains the most widely used standard. However, the Smart Evaporator™ offers a modern alternative that enhances safety and efficiency, especially when dealing with high-boiling-point solvents.

Table of Contents

- 1. How a Rotary Evaporator Works

- 2. How the Smart Evaporator Works (VVC Technology)

- 3. Comparison Table

- 4. Which Evaporator Should You Choose?

- Frequently Asked Questions (FAQ)

- Real-World Use Case

- Conclusion

Ready for Safer, Faster, and More Reliable Evaporation?

1. How a Rotary Evaporator Works

A rotary evaporator removes solvent by applying heat, vacuum, and rotation. Here’s how it works:

Step-by-Step Process

- Rotating the flask: This increases surface area, thereby accelerating evaporation.

- Vacuum application: In this step, the vacuum lowers the solvent’s boiling point for evaporation.

- Condensation and collection: Finally, the vapor condenses in a cooling coil and is collected in a separate flask.

Pros and Cons

- Pros: It is widely adopted, allows efficient solvent recovery, and supports various accessories.

- Cons: However, it requires training, poses a bumping risk with high-boiling solvents, and demands constant monitoring.

2. How the Smart Evaporator Works (VVC Technology)

The Smart Evaporator™ by BioChromato uses Vacuum Vortex Concentration (VVC)—a unique technology that enables sample drying under atmospheric pressure.

Step-by-Step VVC Process

- Suction starts via vacuum pump, initiating the airflow.

- Air flows in through spiral slits in the plug, enabling controlled gas entry.

- Vortex airflow forms inside the container, stirring the sample.

- Surface area increases, which significantly enhances evaporation speed.

- Solvent evaporates and the sample dries directly in the vial.

Pros and Cons

- Pros: This system offers no bumping risk, supports high-boiling solvents (e.g., DMSO), and accepts any container.

- Cons: While highly efficient for micro-volume samples, the Smart Evaporator is not designed for large-scale concentration workflows.

Ready for Safer, Faster, and More Reliable Evaporation?

3. Comparison Table

| Feature | Rotary Evaporator | Smart Evaporator (VVC) |

|---|---|---|

| Concentration method | Vacuum + rotation + heating | Spiral air flow(Atmospheric pressure) + heating |

| Sample pressure environment | A sample is under reduced pressure | A sample remains at atmospheric pressure |

| Bumping risk | High with some solvents | Very low |

| Container compatibility | Special flasks required | Any desired container |

| Ease of use | Needs training | Simple, push-button |

| Solvent recovery | Yes (via condenser) | Yes (using an external condenser or cold trap) |

4. Which Evaporator Should You Choose?

Choose Rotary Evaporator If:

- You need to recover and reuse solvents.

- You have existing rotary-compatible glassware.

- You want a traditional method with lower initial cost.

Choose Smart Evaporator If:

- You’re working with high-boiling or bump-prone solvents.

- You want to simplify evaporation with minimal training.

- You need dry-down for LC/MS or similar workflows.

- You want flexible, container-free operation.

Frequently Asked Questions (FAQ)

Q1: Can Smart Evaporators recover solvents like a rotary evaporator?

Yes. While Smart Evaporators dry samples directly in the container, it is also possible to recover solvents via the exhaust line using an external trap system.

Q2: Is the Smart Evaporator suitable for volatile solvents?

Yes, it handles volatile solvents without any problem. At the same time, its standout advantage is the ability to dry high-boiling-point solvents like DMSO, DMF, and water—something that’s often difficult with conventional evaporators.

Q3: Can beginners operate the Smart Evaporator safely?

Absolutely. Smart Evaporators are designed with intuitive, push-button operation and do not require vacuum or rotational speed adjustments, making them ideal for new lab members or student use.

Q4: Do I need special glassware to use the Smart Evaporator?

No. One of the strengths of the Smart Evaporator is that it works with your desired containers—standard vials, tubes, or glass bottles—no custom flasks required.

Ready for Safer, Faster, and More Reliable Evaporation?

Real-World Use Case: Enhancing Safety and Efficiency in DMSO Removal

Lab Type – Department of Medicinal Chemistry and Molecular Pharmacology, Purdue University (UK)

The research team needed to isolate a platinum (IV) chloride DMSO complex (Na[PtCl₅(dmso)]) from a DMSO-water mixture. Traditional methods like lyophilization were time-consuming and often incomplete. Moreover, the presence of DMSO in formulations posed regulatory challenges, as the FDA does not approve DMSO-containing formulations for human administration.

Solution

The lab introduced the Smart Evaporator™ C1, which operates under atmospheric pressure using Vacuum Vortex Concentration (VVC) technology. This allowed for efficient removal of DMSO without the risk of bumping or sample loss.

Outcome

- Effective removal of DMSO, facilitating the preparation of DMSO-free formulations suitable for animal studies.

- Improved safety and efficiency in handling high-boiling-point solvents.

- Enhanced workflow by eliminating the need for complex and time-consuming traditional evaporation methods.

This case underscores the Smart Evaporator™‘s capability to address specific challenges in pharmaceutical research, particularly in the efficient removal of solvents like DMSO.

Source: BioChromato official website

Conclusion

For optimized workflows, a smart strategy is to use rotary evaporators for pre-concentrating large-volume samples and then transfer them to the Smart Evaporator™ for final drying, especially when working with high-boiling-point solvents.

Rotary evaporators are ideal for efficient solvent removal and recovery on a large scale, while the Smart Evaporator™ excels in safely drying small-volume samples without the risk of bumping.

By combining both systems, laboratories can maximize efficiency, safety, and flexibility in their evaporation processes.

Ready for Safer, Faster, and More Reliable Evaporation?