The Smart Evaporator is used for pretreatment prior to the quantitative analysis of lipid and collagen content, with operation time being reduced by up to one-third!

Professor Keiichi Goto of the Tokai University, Faculty of Oceanography, Department of Fisheries, Food Engineering Laboratory, kindly introduced the Smart Evaporator K4. To get their impression about its use, we interviewed Dr. Yagi and Mr. Kashikura.

In Prof. Goto’s laboratory, scientific research is being conducted into the classification, identification and control of food microbiology, scientific research regarding HACCP, R&D of rapid test methods for microorganisms, R&D of fermented foods, the visualization of characteristics in seafood and processed seafood, and applications utilizing processing methods used in fishery resources.

┃Topics

- Reduction of operation time by up to one-third.

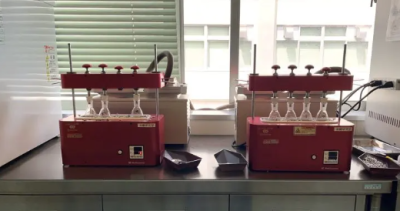

- Simultaneous concentration of up to 6 samples in eggplant flasks using two Smart Evaporator K4 units.

┃Conditions of Use for the Smart Evaporator

< Research Theme >

- Measurement of lipid content in tuna <Bligh and Dyer Method>

- Quantitative method of total collagen in tuna

< Conditions: Research Theme 1 >

- Containers: Lipid bottle (Flat bottom 50 mL vial)

- Solvents: Chloroform 10 mL, Methanol 10 mL, and Potassium chloride 5 mL

- Set temperature: 60℃

- Concentration frequency: Several times/month

- Operation time: 5 – 10 min (⇔ 20 – 30 min before introduction)

- Sample number: 3 samples/time

- Pre- and Post-Process: Extraction of the chloroform and methanol layers after centrifugation (Pre-process), and measurement of collagen content using a spectrophotometer (Post-process).

< Conditions: Research Theme 2 >

- Containers: 50 mL eggplant flask

- Solvent: Hydrochloric acid 5 mL*

- Set temperature: 100℃

- Concentration frequency: Several times/month

- Operation time: 60 - 90 mins

- Sample number: 6 samples/time

- Pre- and Post-Process: Hydrolysis of the extract in the pre-process.

*Please note that this model is not designed to be resistant to acidic solvents. Use with acids is not recommended, as it may result in damage for which the customer assumes full responsibility. For applications involving acidic solvents, we recommend using our acid-resistant model, ACR1.

┃User Impressions after using Smart Evaporator

<Advantages>

- The Smart Evaporator makes it possible to increase the number of simultaneous concentrations, significantly shortening the operation time. Before introducing the Smart Evaporator, the operation time was at least 20 minutes. Now, it typically completes in 5–10 minutes.

- Previously, eggplant flasks were used, which were difficult to keep upright. Now, since concentration can be performed in vials, the containers can stand on their own, making storage much easier.

<Areas for Improvement>

- I found that smaller aluminum beads would be easier to use. Both lipid vials and eggplant flasks were easier to handle with finer beads.

Reporter’s comment

Thank you very much for taking the time to participate in this interview. While reviewing Professor Goto's research, we came across the following article:

Although processed seafood is very familiar in our daily lives, I must admit that I was unaware such research was being conducted. It is truly an honor if the Smart Evaporator is helping to improve operational efficiency in a research field that is receiving growing attention from society.

We sincerely hope that you will continue to find the Smart Evaporator useful in your ongoing and future research.

■Interested in what Smart Evaporator is? You can learn from here!