Multiple evaporations of water or mixed solvents for ingredient analysis pretreatment with the C10!

This time, we had an interview with Ms. O who is using the C10 in her ingredient analysis and the stability study of pharmaceutical products.

Interviewee:

Ms. O, drug-related division in one chemical manufacturer

BioChromato

Thank you for your time today. What types of research are you in charge of?

Ms.O

In my workplace, the development of medicines is carried by two teams, one is the formulation and the other is the analysis team, and I belong to the analysis. We verify ingredients and effective period of external preparations, and we are also developing our own analytical methods. When the target sample has low concentration, a trace ingredient cannot be detected so we use the Smart Evaporator C10 for evaporation.

BioChromato

How was the impression so far?

Ms.O

For the pretreatment, I feel convenient that the C10 can handle whatever the quantity or the kind of solvent is. Thanks to that, I could reduce the operation time by more than 4 hours.

BioChromato

It’s our pleasure. What kind of containers and which sized is used in conjunction with your Smart Evaporator? And also where did you put the C10?

Ms.O

We utilize 50ml screw-tube and 10ml screw-tube test tubes as containers, and we concentrate mainly water or a mixture of solvents such as water and acetonitrile, methanol, etc. The sample volume can range from less than 1ml to as much as 150ml at the most, but I dry up in volumes in the approximate 1ml to 20ml range, depending on the container. Also, when performing liquid-liquid extraction, solvents such as chloroform and hexane are sometimes used, but there are no devices that can be used for these solvents, which is surprising, so the device is very useful.

For installation, both the main unit and the vacuum pump are placed inside the draft.The room temperature is set at 25°C to avoid heating the sample as much as possible, since some chemicals may be damaged by heat.

BioChromato

Thank you for all the details. What did you use before the Smart Evaporator? How did it reduce by 4 hours?

Ms.O

Up to now, I was using the freeze dryer, the centrifugal evaporator, the nitrogen blowing system and the rotary evaporator. I choose these according to the samples.

BioChromato

Do you select the one according to the sample numbers and kinds?

Ms.O

Yes. Some samples contain organic solvents and their capacity varies, so we place each device within reach in the lab.

BioChromato

Four types of freeze drier, centrifugal evaporator, nitrogen blowing device, rotary evaporator are provided and I feel that it is quite well equipped… How did you actually use those properly?

Ms.O

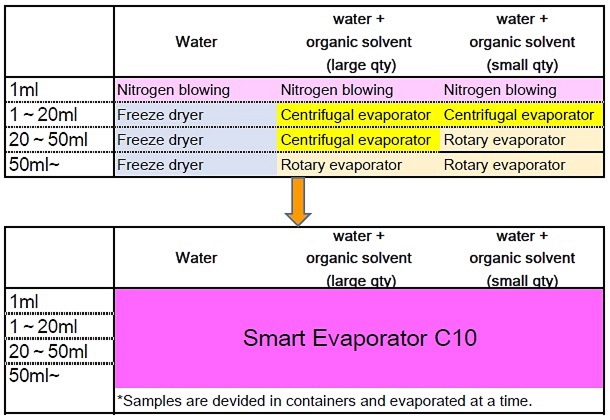

Basically, the sample with 100% water is concentrated by the freeze dryer, but if that contains the organic solvent, it cannot be evaporated as it is by the freeze dryer, so as a pretreatment we use the rotary evaporator to evaporate the organic solvent. The centrifugal evaporator is used for the sample quantity like 20ml, and the nitrogen blowing system for the small amount sample like 1 ml or less. (Picture shown: Nitrogen blowing system in the lab)

BioChromato

So when they contain organic solvents, or depending on the sample quantity, did you have to select the appropriate evaporating method?

Ms.O

That’s right. We first have to evaporate the organic solvent, and the rest will be evaporated by the freeze dryer. So the appropriate method was selected depending on the sample quantity and whether that contains the organic solvent. However, I felt uneasy for the organic solvent aspiration if that causes damages to the oil type vacuum pump. Also the oil change and the liquid nitrogen replenishment for using the trap were troublesome.

BioChromato

I see. Because our system recommends an oil-less diaphragm vacuum pump at low vacuum, it saved the labor for oil exchange. Do you mean this fact was also an important factor for selecting the product??

Ms.O

Yes. We handle many samples containing organic solvents, so when we found about you at the JASIS exhibition booth, it attracts me that your system evaporates the organic solvent without changing the oil. I thought I would definitely want that if there’s a multi-position model to process 5-10 samples at a time. Since after the C10 is introduced, we became able to handle various samples with one device, so the workability was much improved as expected. In the past, we had to keep our eyes on the freeze dryer for an hour to watch out bumping and then leave that overnight, but sometimes it did not complete even in the next morning. If the vacuum condition was not so well, the bumping tends to occur easily. However, for evaporating the samples that easily hold moistures with your system, we see the moistures left in a trace amount. So in such case, we use the centrifugal dryer for completely dry. We only have to dry the trace moisture, so could still significantly shorten the operation time. (Reference below: Comparison chart)

BioChromato

The Smart Evaporator is not influenced by the vacuum condition, there is no risk of bumping, so you can greet the next day with confidence. From what I found from you today, even with a mixed solution of water and organic solvent, we could provide the remarkable workability improvement by being able to carry out the evaporation without considering the load on the equipment. Thank you for today.

Ms.O

Thank you, too.

Summary

In her laboratory, four types of equipment such as a freeze dryer, a centrifugal evaporator, a nitrogen blowing system, and a rotary evaporator were appropriately selected for evaporating water, sample mixed with water and organic solvents depending on their quantity.The C10’s characterized features are the simultaneous evaporation of water and organic solvent at a time, the oil-less vacuum pump, the bumping-free, and the multiple sample processing at a time. So these contribute to the significant improvement in her workability. Even with the large number of analysis pretreatment, our system is a universal design to handle various types of solvents in multiple numbers. From this interview, I felt the C10 would contribute to the field of pharmaceutical development further more.

(Interviewer: Kikuchi)

■Interested in what Smart Evaporator is? You can learn from here!

■Product details of Smart Evaporator C10 (10 channel evaporator)