RAPID EPS Evidence Sheet

-Prevention of cross contamination-

>PDF Download :Prevention of cross contamination

Summary

For plate seals, it is vital to prevent cross contamination between wells. Therefore, we evaluated the prevention level of RAPID EPS by shaking a plate sealed with RAPID EPS at 1000rpm. The absorbance and direct observation showed RAPID EPS prevented cross contamination between wells.

Method

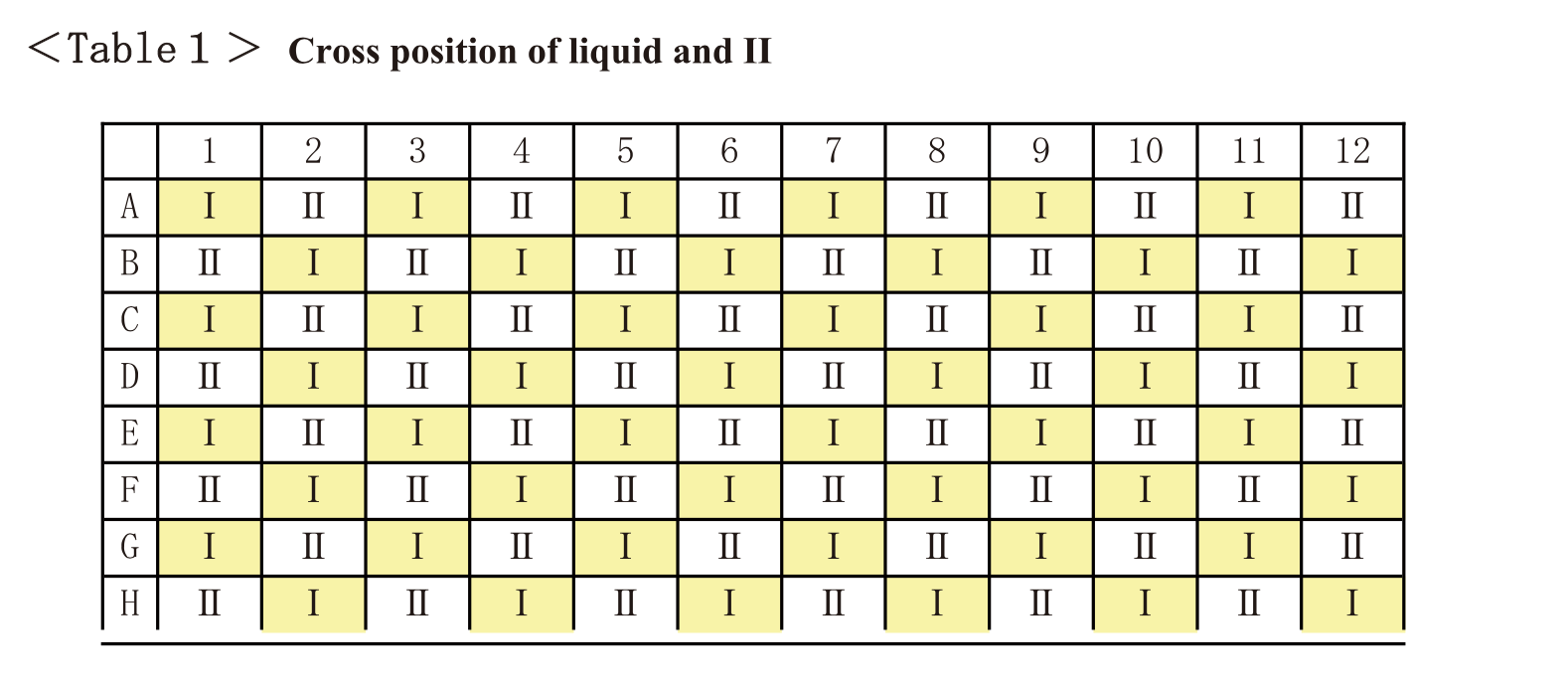

The contamination prevention level was evaluated by using liquid I and liquid II, which colors after being mixed each other. These liquid were dispensed in the shaped of a checkered pattern in 96 well plates. Then, the plate was sealed with RAPID EPS, then was shaken at 1000rpm for 24 hours at 40 °C . The absorbance variation was measured before and after the shaking incubation.

Details of liquid were below.

Liquid I:Fe2+ Solution

Ferrous ammonium sulfate hexahydrate 18.0g

Ascorbic acid 2.0g

Pure water 100mL

Liquid II: Phenanthroline Solution

1,10-phenantroline hydrate 2.0g

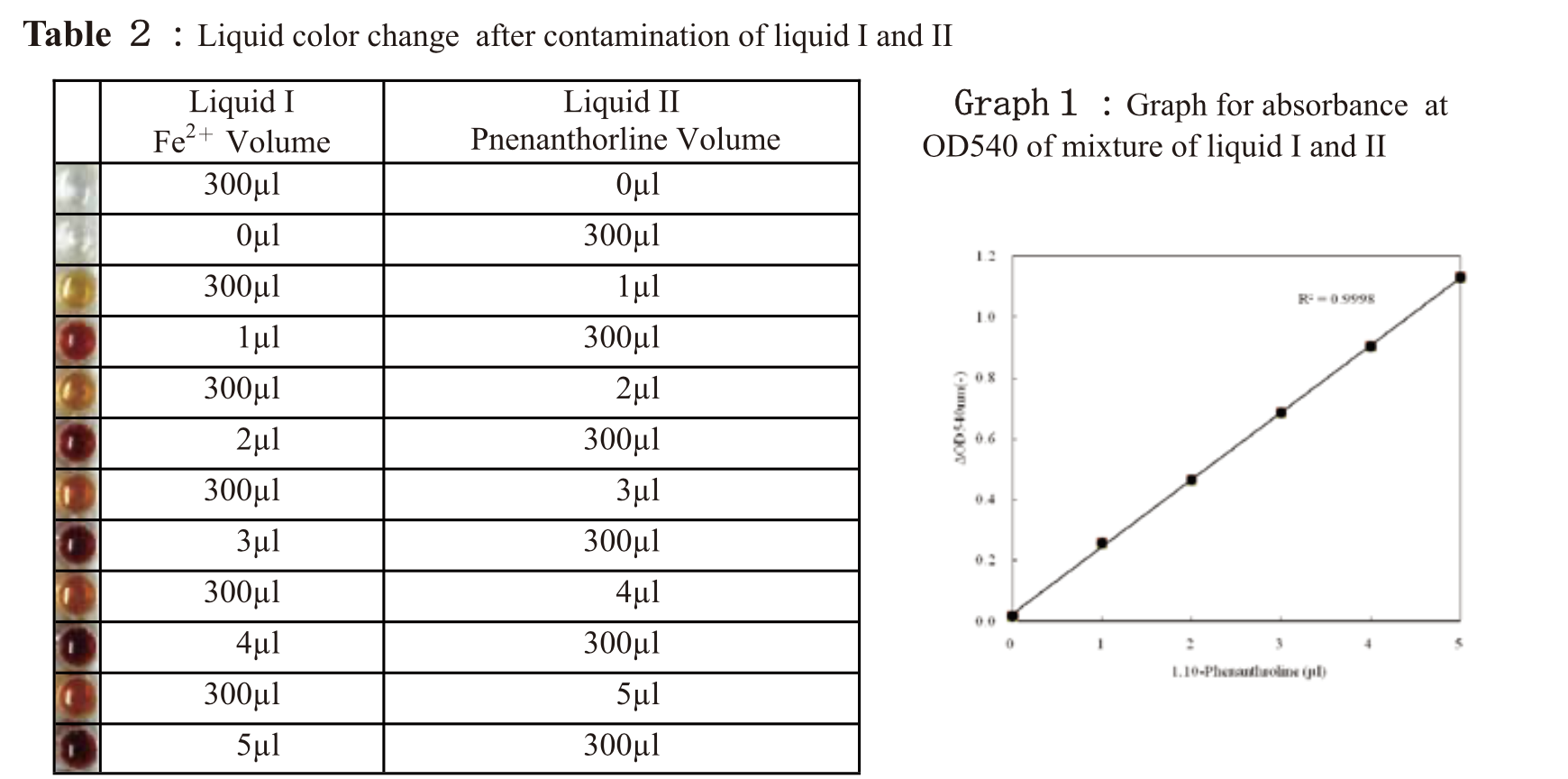

Sodium acetate buffer (pH 4.6) 100mL On the occurrence of contamination and mixing between wells of liquid I and II, the red complex of Fe +and phenanthroline is formed under acidic condition. The absorbance of complex was detected at 540nm.Micro plate is 96 well assay plate (3881-096, material :Polystyrene, flat bottom, well volume: 0.35mL)Each liquid of 300μL was dispensed as showed below.

Evaluation of cross contamination

The addition of 1μL of liquid II to liquid I increased absorbance by 0.2 at OD 540nm. In the case of the addition of liquid I to liquid II was calculated using molecular concentration ratio of two liquids, which revealed that approximately 0.1 μL increased absorbance by 0.2 at OD 540nm.

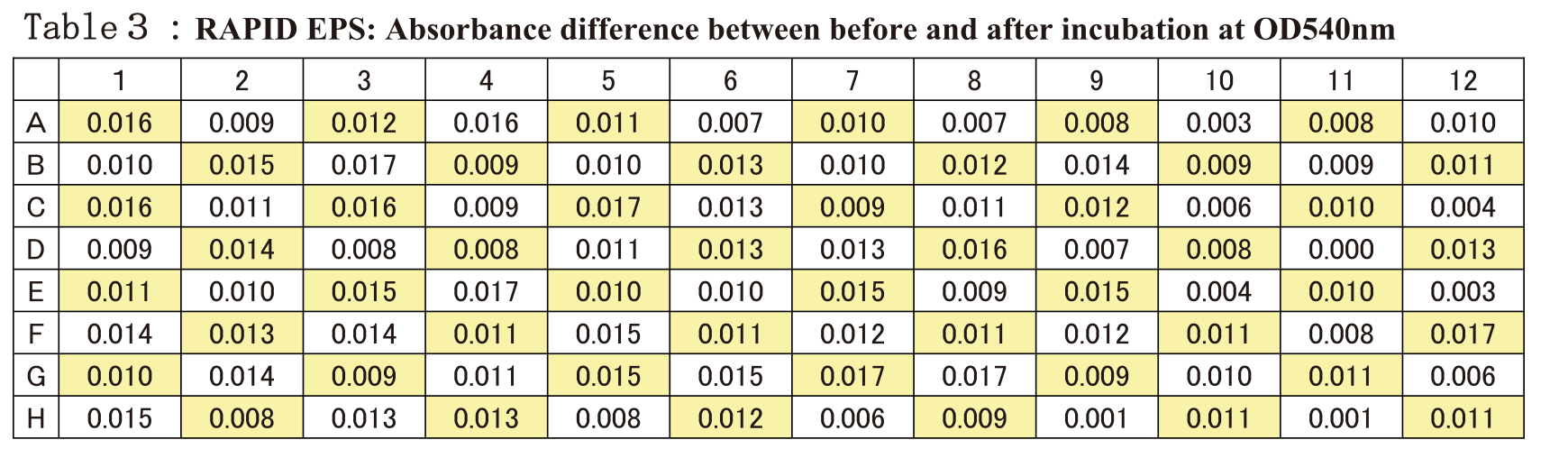

From these results, it was concluded that contamination should have occurred when the absorbance change was more than 0.2 before and after incubation.

Result

The absorbance gap between before and after shaking incubation was less than 10% of the pre-set evaluation standard above (Table 3). Then, color change was not observed. These results concluded that RAPID EPS pre vented cross contamination (Figure 1). The red coloring spot observed outside wells was because of droplets of liquid I and II clinging to seals dropped on the outside wells, which was not cross contamination.

Any questions? Here are our answers to the most commonly raised questions.