A Simple and Safe Way to Evaporate Solvents: Smart Evaporator Basics

Many researchers face challenges when concentrating samples, especially when working with high-boiling solvents or small volumes. The Smart Evaporator is one option designed to address these challenges in a simple and controlled way.

This article explains what the Smart Evaporator is, how it works, and what to prepare before starting, helping readers understand whether it may fit their workflow.

Who This Guide Is For

This guide is recommended for people who:

- Are looking for a simple way to remove solvents from samples

- Are struggling with high-boiling solvents such as DMSO or DMF

- Want to evaporate solvents with less risk of bumping

- Are exploring alternatives to conventional evaporation methods

- Have never heard of the Smart Evaporator, but want to understand new approaches to solvent evaporation

Table of Contents

- What is the Smart Evaporator?

- How does it work?

- How can it be bumping free?

- What to prepare before starting

- Applicable containers

- Spiral Plug selection and installation

- Airflow settings

- Heating considerations

- Care and Cleaning Requirements

Ready for Safer, Faster, and More Reliable Evaporation?

Q1: What is the Smart Evaporator?

A: The Smart Evaporator is an evaporator used to remove solvents from samples.

In conventional evaporation, samples are often concentrated by suction under reduced pressure using a vacuum pump. The Smart Evaporator uses a proprietary plug called the Spiral Plug, which enables solvent evaporation and concentration with a reduced risk of bumping.

Q2: How does it work?

A: The Smart Evaporator applies a concentration method known as vacuum vortex concentration.

The Spiral Plug, which has a groove on its surface, is placed on the container mouth. When suction is started using a vacuum pump, air enters through the groove and generates vortex airflow inside the container.

This airflow stirs the sample and increases the liquid surface area, which helps accelerate solvent evaporation.

Q3: How can it be bumping free?

A: As vacuum suction is applied, air is continuously drawn into the container through the groove.

This ongoing air intake prevents the pressure from reaching a fully developed low-vacuum state, thereby reducing the likelihood that the solvent reaches its boiling point and bumps.

Q4: What do you need to prepare before starting evaporation?

A: To start evaporation, prepare the following items:

- Sample containers for evaporation

- A vacuum pump

Once these are set up together with the Smart Evaporator, the system is ready to start operation.

Ready for Safer, Faster, and More Reliable Evaporation?

Q5: What are the applicable containers?

A: Applicable containers are those with a mouth inner diameter of 4–32 mm and a height of 120 mm or less.

You may also use micro tubes or vials, which allows samples to be evaporated directly without transferring them between containers. Containers should be prepared separately by the user.

Q6: How should the Spiral Plug be selected and installed?

A: Select a Spiral Plug size (P1–P5) that matches the inner mouth diameter of the container.

Insert the Spiral Plug fully and evenly into the container mouth. No alignment or orientation of the groove is required.

Q7: Can airflow be adjusted?

A: Yes. The Smart Evaporator allows airflow to be adjusted depending on the sample and operating conditions.

Confirm the airflow setting before starting evaporation and adjust it as needed during setup.

Q8: Is heating necessary during evaporation?

A: If insufficient heat is applied, evaporation may not proceed efficiently.

For thermally stable samples with no risk of thermal degradation, heating is recommended.

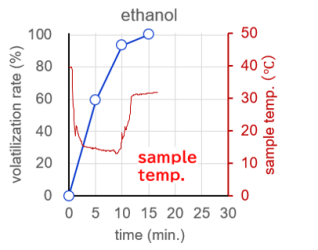

Without heating, the sample temperature can decrease due to evaporative cooling (latent heat of vaporization), which may slow evaporation.

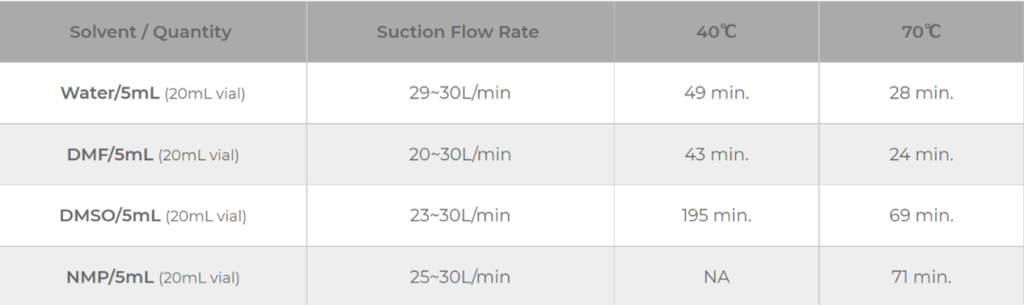

As shown in the table, applying heat significantly shortens evaporation time across a range of solvents, including water, DMF, DMSO, and NMP.

By compensating for the temperature decrease during evaporation, heating supports more efficient and predictable solvent removal.

Q9: How much care and cleaning does the Smart Evaporator require?

A: The Smart Evaporator is designed for simple operation and minimal routine maintenance.

To reduce the risk of contamination or sample carryover, cleaning the Spiral Plug after use is recommended, especially when processing different samples.

When appropriate, the plug can be rinsed with ethanol or other suitable solvents (e.g., acetone or IPA), then dried before the next sample run.

Ready for Safer, Faster, and More Reliable Evaporation?