Essential for concentrating water-containing samples during LC preparative isolation, and crystallization in single-crystal X-ray analysis. Direct concentration in 2 mL glass vials minimizes sample loss!

We had the privilege of speaking with Dr. Futa Sakakibara, Executive Director of the Novel Compounds Exploration Research Organization (NERO), based in Tsukuba, Ibaraki Prefecture. Dr. Sakakibara is dedicated to exploring unknown chemical substances in the fields of new food development, agricultural production technology, and food safety. He shared valuable insights and feedback on our products.

Organization: Novel Compounds Exploration Research Organization (NERO)

Interviewee: Dr. Futa Sakakibara, Executive Director

Lab Location: ORIENTAL GIKEN INC. (X/S WORKSITE)

NERO Website: https://g-nero.or.jp

┃Topics

- Improved recovery rates for heat-sensitive compounds by drying water without applying heat!

- Significantly reduced sample loss by concentrating directly in 2 mL vials!

- Perfect for the crystallization process in single-crystal X-ray structure analysis!

┃Research contents and purpose of concentration

Our mission is “To help create a safe and secure world free from concerns about unknown substances,” based on the idea that the substances visible to our eyes represent only a tiny fraction of everything found in nature. In particular, by establishing the Subcommittee of New Food Development Research (functional ingredients, health food ingredients, fermented food), the Subcommittee of Agricultural Production Research (plant growth promotion/suppression, insecticides/repellents/attractant active substances, biostimulants), and the Subcommittee of Food Safety Research (residual pesticides, pollutant environmental dynamics, persistent organic pollutants), the Novel Compounds Exploration Research Organization (hereinafter referred to as NERO) focuses on the preparative purification of unknown components in each field using HPLC and determining the chemical structures of these substances with a single-crystal X-ray structure analyzer.

Recent progress in single-crystal X-ray structure analyzers has been remarkable; this technology enables the determination of the chemical structures of ultrafine crystals that could not previously be analyzed. To expand the application of this new analytical technology to the study of agricultural chemistry, we are developing novel component exploration research in collaboration with Rigaku Corporation, the manufacturer of single-crystal X-ray structure analyzers. Preparative isolation by LC, concentration, and crystallization are essential for determining the chemical structures of very small amounts of secondary metabolites. A Smart Evaporator is utilized to dry down samples during the pretreatment process using LC, before analysis with the single-crystal X-ray structure analyzer.

┃Conditions used with the Smart Evaporator

- Model: Smart Evaporator C1

- Containers: 2mL glass vial, pear-type flask (suitable for air blast concentration)

- Solvents: Water, acetonitrile, acetone, methanol, ethanol, hexane, ethyl acetate, 500μL - 50mL

- Set temperature: Ambient - 100℃

- Sample: Functional ingredients contained in food, agricultural products (rice, mushroom, fruits), and unknown ingredients peaks generated after material decomposition.

- Concentration frequency: Dozens of times per day

- Operation time: 5 – 30 min/time

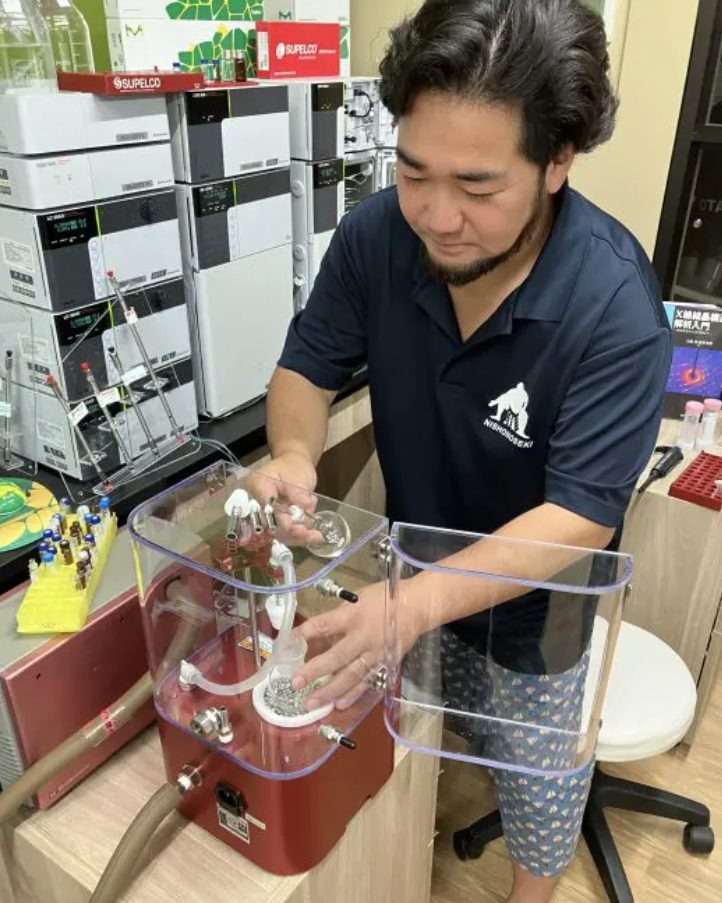

- Instrument location: The Smart Evaporator must be located next to the LC system to allow repeated LC preparative isolation and exsiccation.

┃Reason for selecting the Smart Evaporator/ Work after installation.

We first saw the products demonstrated by BioChromato Inc. during JASIS at Makuhari Messe.

Observing how water could be concentrated effortlessly, without bumping, and with minimal supervision in a compact setup convinced us that this is the ideal device for crystallization in single-crystal X-ray structural analysis.

┃Impression after using Smart Evaporator

<Advantages>

The time and effort required for drying the mobile phase solvents during LC preparative isolation were dramatically reduced. In addition, the recovery rate of heat-sensitive compounds improved by exsiccating water without applying heat. As a result, we decided to adopt the same approach for exsiccating water samples before conducting conventional condition studies for solid-phase extraction columns.

After passing samples containing organic solvents through a solid-phase extraction column, the Smart Evaporator is used to evaporate the organic solvents, leaving the samples in a water-rich state. This enables the samples to be quickly passed through a reverse-phase solid-phase extraction column for further processing.

Conventionally, a rotary evaporator is used, which often results in significant sample loss due to the large-sized glass container. However, the Smart Evaporator allows concentration from a 200 mL flask to a 2 mL glass vial simply by changing the attachment, significantly reducing sample loss. Since the introduction of the Smart Evaporator into our laboratory, we have been able to efficiently purify samples without any loss caused by transferring between containers. For LC preparative isolation of trace amounts of unknown component peaks, target peaks are collected into a 2 mL glass vial and dried using the Smart Evaporator. Collecting target peaks multiple times in the same vial effectively enables sample purification without the risk of loss from container transfers.

<Challenging targets>

We look forward to the development and commercialization of a fully automated device for pretreatment processes compatible with trace preparative LC, utilizing the Smart Evaporator.

As shown in the photo, we are currently placing the Smart Evaporator right next to the LC system and drying the collected samples after LC preparative isolation. The dried vials are then used for further collection. Repeating this process minimizes sample loss and concentrates the samples to a level suitable for crystallization.

Most existing peripheral devices, such as fraction collectors, are designed for preparative columns (e.g., flow rates of 5 mL/min). However, the preparative work conducted at the NERO laboratory is performed on a smaller scale using column sizes typically employed for analytical purposes (length: 25 cm, inner diameter: 4.6 mm, particle size: 5 µm, and flow rates 1 mL/min or lower). The reason for this is that in single-crystal X-ray structural analysis, where even fine crystals can be analyzed, the quality of the sample (with a chromatographic purity target of 99%) is prioritized over quantity. This requires using multiple LC columns with different interactions during the preparative purification process.

Using preparative columns makes it difficult to achieve clean baseline separation for trace samples. Additionally, preparative column options are often not available as standard products from column manufacturers. This leads to longer procurement times (custom orders have extended lead times) and higher costs (specialized preparative columns with unique packing materials can exceed 1 million yen per column). For these reasons, we have adopted the use of various analytical-scale columns. As single-crystal X-ray structural analysis is expected to play an increasingly prominent role in future research on unknown substances, the development of automated pretreatment devices that align with the workflow described above and utilize readily available column products would significantly advance our goal of creating "a world free from concerns about unknown substances."

Summary

We would like to thank Dr. Sakakibara for taking the time to meet with us. We are delighted to hear how the Smart Evaporator has made a valuable contribution to his laboratory's workflow, and we were captivated by his unique insights.

We could feel his strong passion for the analysis of unknown substances when he discussed that "safe and secure manufacturing should not ignore unknown peaks, but this requires an accurate analysis method for quality control." Furthermore, we recognized a strong desire for the development of an automated pretreatment system from his comment that "the development of a pretreatment system tailored to the needs of single-crystal X-ray structural analysis would enable quick investigation of unknown peak components, which has been a persistent challenge in the chromatographic field."

Thank you very much for sharing your valuable opinions, Dr. Sakakibara. We will do our best to meet your expectations.

(Reported by Kikuchi and Ota, BioChromato, Inc.)

■Interested in what Smart Evaporator is? You can learn from here!