Analysis of Fluoro Rubber

Purpose

Fluoro rubber is a type of rubber known for its excellent heat resistance and chemical resistance. Measurements of fluoro rubber with different usage histories were conducted to investigate the degradation of the polymer over time.

Methods

| Ion Source | ChemZo (BioChromato) |

| Mass Spectrometer | compact QTOF (Bruker) |

| Measurement Method | Small pieces of new and long-term used fluoro rubber with different usage histories were heated from room temperature to 600°C using a temperature gradient device while measuring mass spectrometer (negative mode). |

| Data Processing | TIC and the repeating units of fluoro rubber were extracted and compared using Polymer Engine and DataAnalysis. |

Results 1

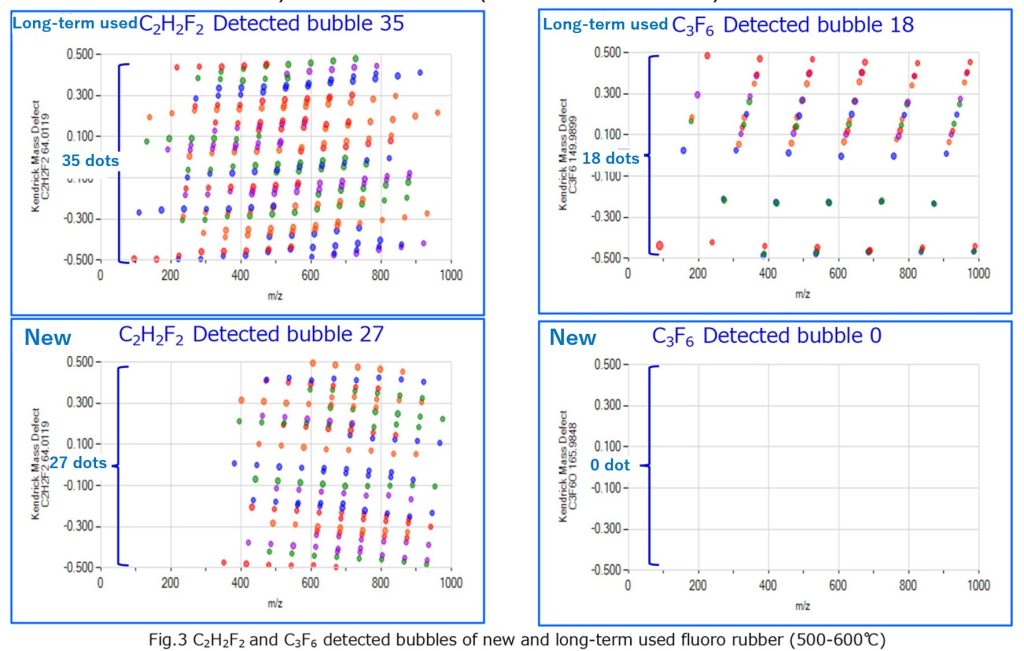

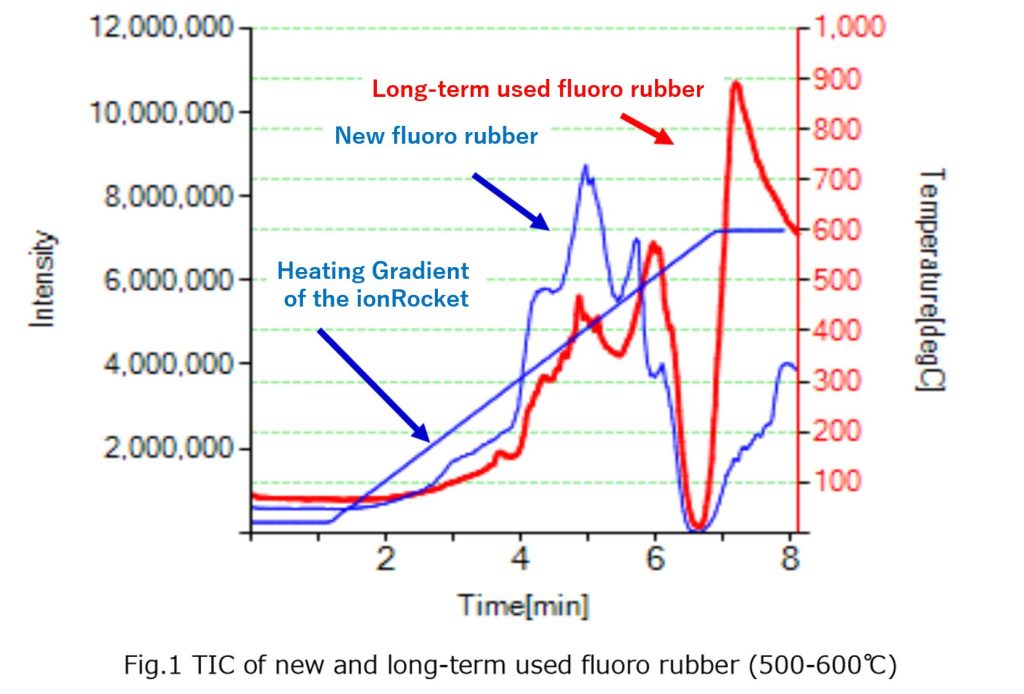

The TIC is shown in Fig.1. In the high-temperature range (500-600°C), the TIC intensity of the long-term used sample was several times higher. This is likely due to more extensive degradation of the resin in the long-term used sample, resulting in the detection of more thermal desorption components at higher temperatures. The mass spectrum for the high-temperature range is shown in Fig.2. Although the intensities differ, it can be seen that the mass spectra are similar. However, due to the complexity of the mass spectrum, it is difficult to examine it and identify the repeating structures originating from the monomer.(Fig.2)

Results 2

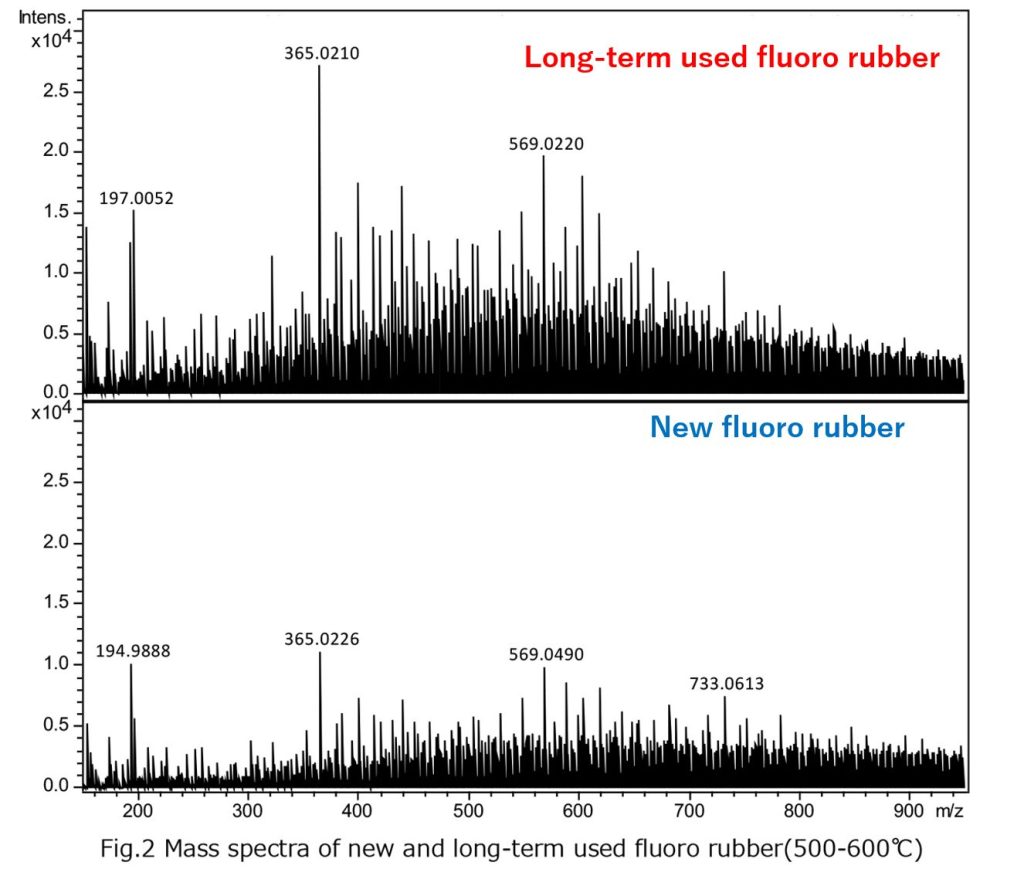

Fig. 3 shows the data processing results (bubble plot) generated by Polymer Engine. This software extracts repeating units of resins derived from monomers from mass spectra and is highly effective for analyzing complex mass spectra like those in Fig. 2. The data processing results revealed that the long-term used product had more detections of the repeating units C2H2F2 and C3F6, which are characteristic of fluoro rubber, compared to the new product. Notably, C3F6, which was undetected in the new product, was detected 18 times in the long-term used product. The differences observed in the bubble plot and TIC at high-temperature ranges are likely due to the deterioration of the fluoro rubber in the long-term used product compared to the new one. By combining ChemZo with a temperature gradient device for mass spectrometry and employing Polymer Engine for spectral analysis, it was possible to compare the degree of resin aging and degradation over time.

Note: The number of detections (e.g., 18) is counted as a group of bubbles aligned horizontally with equal Kendrick Mass Defects (KMD), with groups containing five or more bubbles considered as one.